Coal Will Keep the Lights on: How to Mitigate the Climate Risk

Coal, a fossil fuel, is the largest source of energy primarily used to produce electricity and heat through combustion. Coal gasification can be used to produce syn-gas, which can be further transformed into transportation fuel such as gasoline and diesel. Coal can also be directly liquefied into diesel through highly sophisticated techniques. Coal liquefaction is one of the backstop technologies that could potentially limit escalation of oil prices. Coal will have a key role to discharge in the overall energy mix. In a developing country like India, growth in energy consumption is entwined with economic growth. Coal, being a cost-effective energy resource in contrast to a very low hydrocarbon resource potential, remains the focus of attention of energy planners ever since the oil crunch of the early '70s.

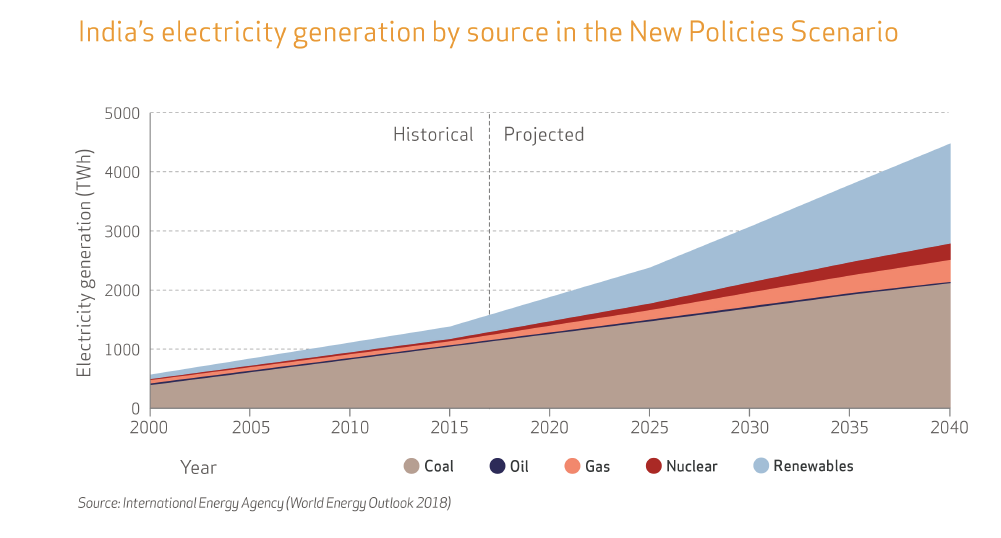

In the Indian context, the increased focus on urbanization, industrialization and infrastructure development will necessitate significant increase in power generation in which coal will play a major role.

Further, coal finds major use to meet the process and captive power requirement in the production of steel, cement, aluminium, paper, chemicals, pharmaceuticals and advanced materials such as activated carbon, carbon fibre, and silicon metal/silanes.

This scenario demands development and implementation of strategies that will help us not only in meeting our energy demands but also mitigate the climate change risk. Some key strategies that can enable us to achieve the goal are listed below:

- Application of Advanced Technologies and Carbon Substitutes in End-Use Industries: All the upcoming coal-based power plants should operate on super critical technology to reduce the fuel rate and consequent GHG emissions. All power plants irrespective of their distance from the pit head should be required to use only washed coal. Also, substitution of carbon as a process requirement in end-use industries such as steel, which are naturally dependent on carbon on reduction of iron oxide, should be explored. MIT-based start-up Boston Metal has developed carbon-free metal-oxide electrolysis-based iron-and-steel-making technology. Pilot studies of the technology have been successful and efforts are underway to scale-up and commercialize the same.

- Becoming Early Adopters of Carbon Mitigation Technologies such as CCS (Carbon Capture and Storage): Carbon capture and storage, or CCS, is a family of technologies and techniques that enable the capture of carbon dioxide (CO2) from fuel combustion or industrial processes, the transport of CO2 via ships or pipelines, and its storage underground, in depleted oil and gas fields and deep-saline formations. This technology can only enable effective disposal of CO2 but also help in commercial utilization of CO2 by substituting natural gas in enhanced oil recovery in depleted oil fields. FINNCAP[1] project launched to examine CO2 capture infrastructure options for a CCS demonstration in Finland for capturing 2.6 MTPA of CO2 and transporting over a distance of ~ 2000 km from a 565 MW power plant project has estimated a CAPEX & OPEX of 20.9 Million-Euros/Annum and 11.8 Euros/T of CO2 respectively for CO2 transported by ships and CAPEX & OPEX of 77.2 Million-Euros/Annum and 32.1 Euros/T of CO2 respectively for CO2 transported by pipelines. It is important to note here that given the scale of CO2 generation and heavy CAPEX it would be prudent to develop aggregated and common CCS network or an UBER for CCS. Teesside collective is working on a similar strategy. Teesside Collective is a cluster of energy-intensive industries with a shared vision: to establish Teesside as the go-to location for future clean industrial development by creating a Carbon Capture and Storage (CCS) equipped industrial zone. The project offers a compelling opportunity to progress the UK’s industrial and environmental interest’s hand-in-hand.

- Shifting focus on greater use of Non-Fossil based energy sources in production of plant & machinery for renewable energy generation to minimize scope – I & II emissions: Going forward we have a solid strategy to enhance energy generation through renewable energy sources but the best results will be achieved only if the fossil fuel intensity in the renewable value chain is minimized. For e.g. manufacture of plant & machinery for solar & wind power will involve usage of large amounts of steel, glass, cement etc. which consume large amounts of coal in process and for energy needs. Moving to usage of larger share of non-fossil based energy sources in the production of these materials and building focus on CCS as explained above will enable circularity and reduce scope-I&II emissions to a considerable extent.

Thus, there is an imminent need to deploy these mitigation tools to minimize the risk to the environment and move towards a carbon neutral economy.

*Shantanu Rai is Consultant, NITI Aayog. Views expressed are personal.

Energy Procedia 4 (2011) 2425–2431, Elsevier

National Portal Of India

National Portal Of India